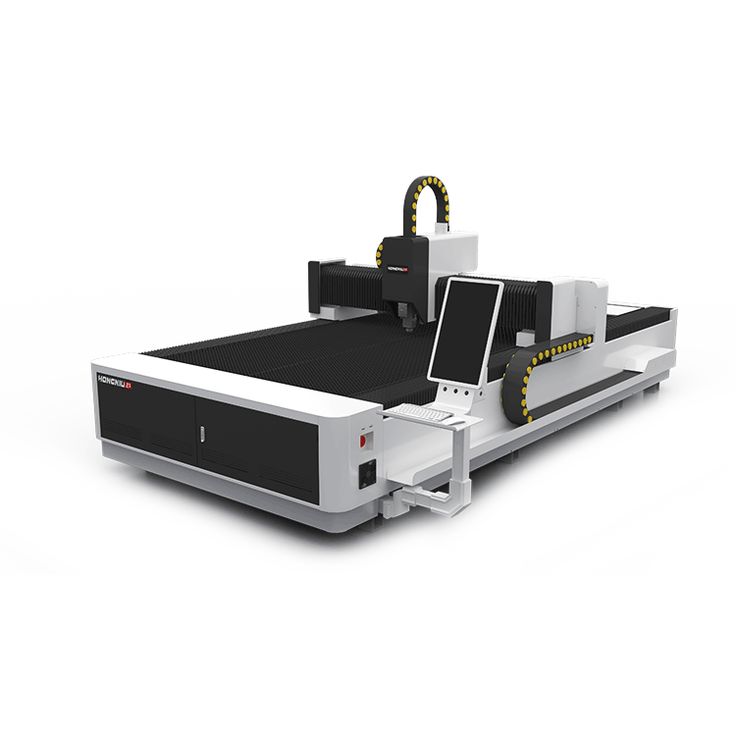

Equipped with multiple laser cutting systems, deburring units, auto-loading turret setups, chamfering, and in-house threading capabilities, ASB Engineering Services operates round-the-clock to ensure fast lead times, consistent quality, and exceptional technical support—all at competitive pricing.

We deliver thousands of precision laser-cut components daily—custom-engineered to match your exact specifications. Backed by deep expertise and industry-leading knowledge, we ensure every part meets the highest standards of quality and accuracy. Our modern manufacturing setup features advanced, integrated laser cutting systems that enable fast, efficient, and repeatable production.

Our advanced setup supports a wide range of materials, equipment, and secondary operations, ensuring flexibility and high-quality outcomes.

We blend advanced technology, industry expertise, and dedicated customer support to deliver high-precision laser-cut parts tailored to your application.