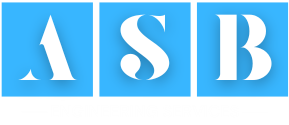

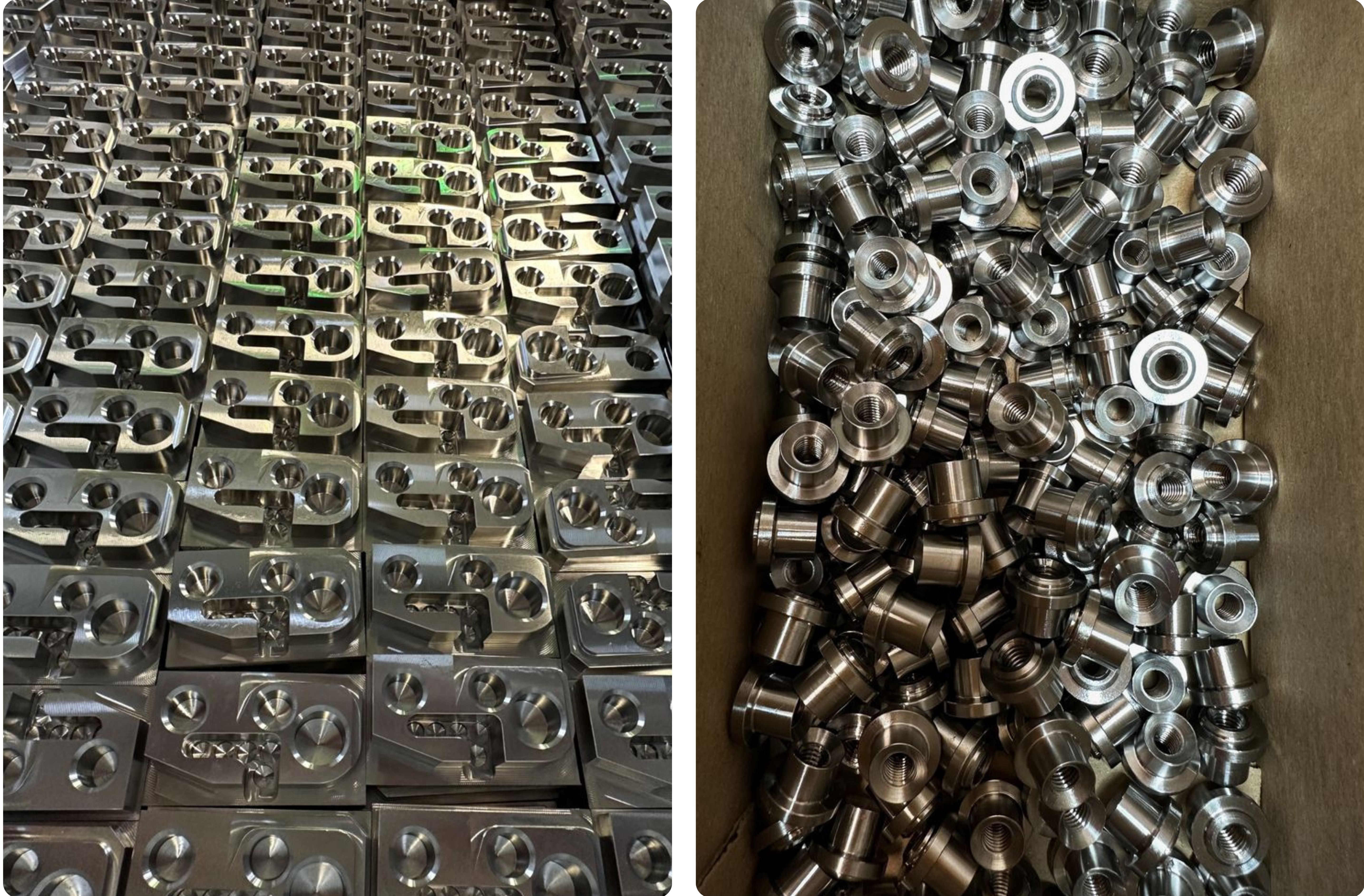

Delivered custom-machined aluminum enclosures and brackets for a global electrical OEM. Each part required tight tolerance machining followed by anodizing for corrosion resistance and enhanced durability.

Impact

ASB’s precision and consistency reduced the client’s assembly line rejections by 40%, ensuring efficient product rollouts to their global customers.

- Building the future with ideas

- Engineering the better way

- Designing future with excellence

- Discovering possibility in manufacturing